3D Printing is the rave. It is exploding onto the manufacturing marketplace. It is latest competency that can take your concept and idea and turn it into a reality. Many engineers and innovators continue to make gigantic strides with the ceiling of 3D Printing. Houses, cars and 3D printed prosthetic hands are examples of products being made. All great advances for the manufacturing world and our society.

Still most design engineers are still utilizing 3D printing to prove out their concepts and provide tangible prototypes prior to production to confirm fit and function of their product. 3D Printing is ideal for quick turnaround, low-cost components to assist in the final approved production design. In years past, 3D printing was limited to only a few materials, but today many engineering grade materials and high-performance materials are being used. Materials like Polypro and ABS material has always been a commonplace, but now high-performance materials like PEEK and Ultem® are being utilized to produce prototypes for critical applications.

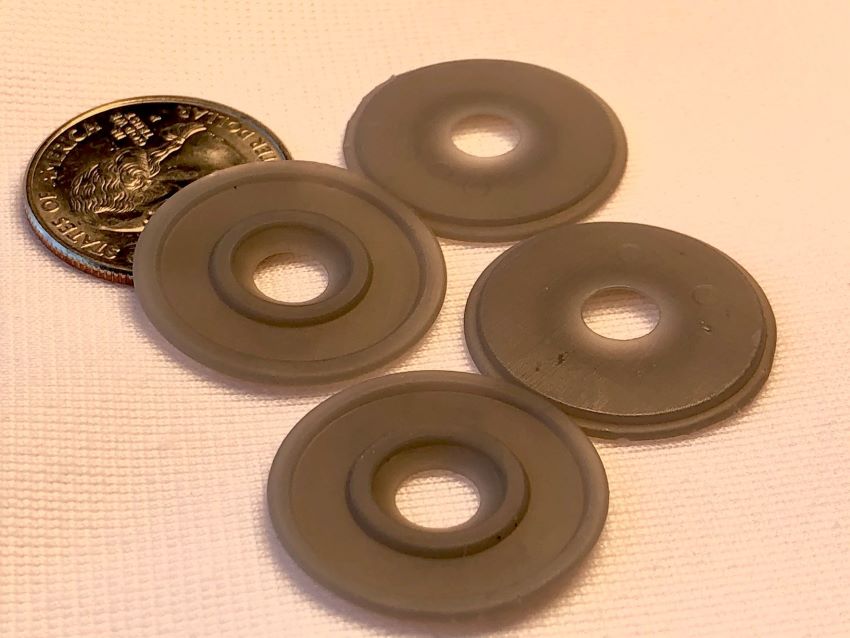

The parts above were produced in 1 day with a provided 3D Solidworks file to Next Level Manufacturing. The 3D printer was able to provide four different components with four different diameters. Each component has a variant diameter of .010” larger to confirm the snap function in which the assembly these parts will go in. The engineer was able to determine the fit and function of the assembly and thus proving out his design.

Top Benefits of 3D Printing:

Design and Product Testing

Cost Effective

Quick Turnaround Time

Mitigated Risk

Creative Possibilities

Assortment of Available Materials

Various colors

Industries Used: All