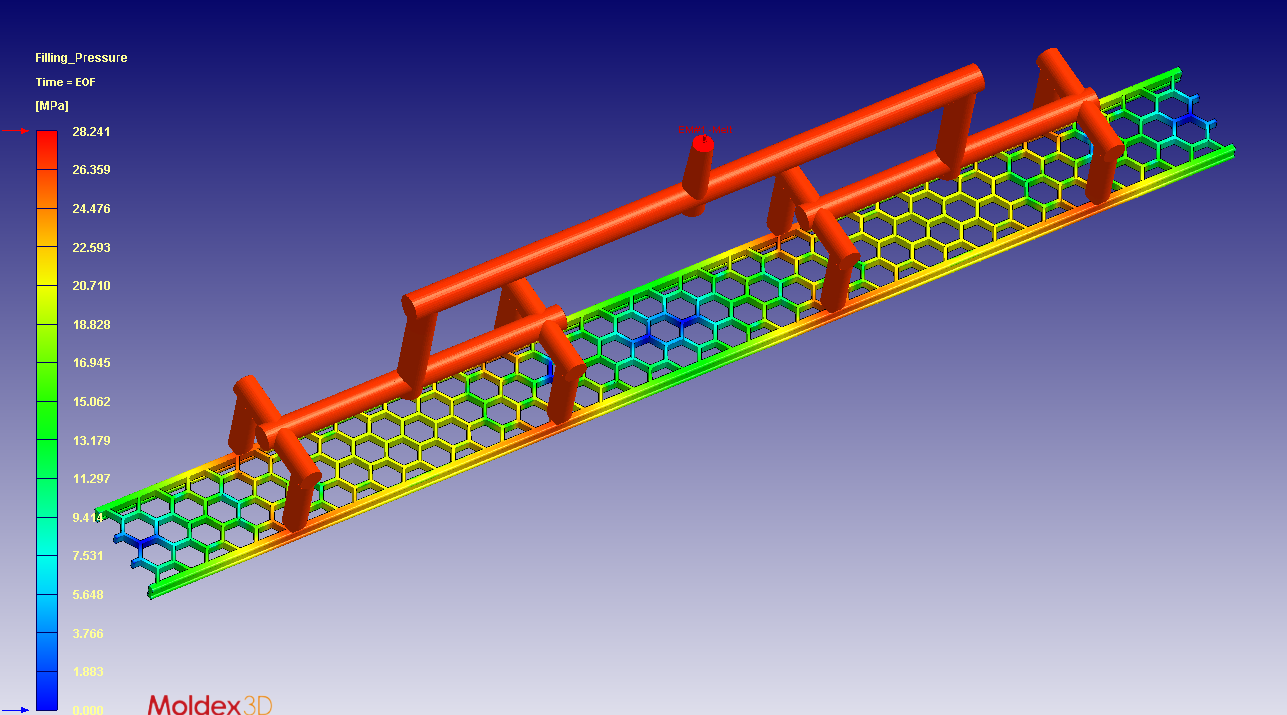

Mold flow analysis is the process that allows NLM to work with clients to simulate the injection molding cycle. This allows NLM to work with the client to analyze results and assess any needed tweaks. NLM will utilize Mold Flow analysis with clients prior to the injection molding process on complex components to ensure that any issues are identified prior to sampling. By NLM assisting the client in providing a Mold Flow Analysis report, we can identify heating/cooling issues, fill/material flow patterns, pressure, air traps/bubbles, stress as well as other potential issues.

Utilizing mold analysis, it helps ensure that from prototype to production that the product will process as optimally as possible. Mold Flow Analysis help elevate the level of quality prior to manufacturing. Mold Flow Analysis reinforces the mold design or assists in providing needed design changes prior to sampling by pointing out potential tool design related molding problems. Based on geometry and tolerances, NLM can develop guidance and suggestions to improve the process of your product. If you have a complex design that needs to be brought to market, utilizing a Mold Flow Analysis will provide your product the best chances for success.